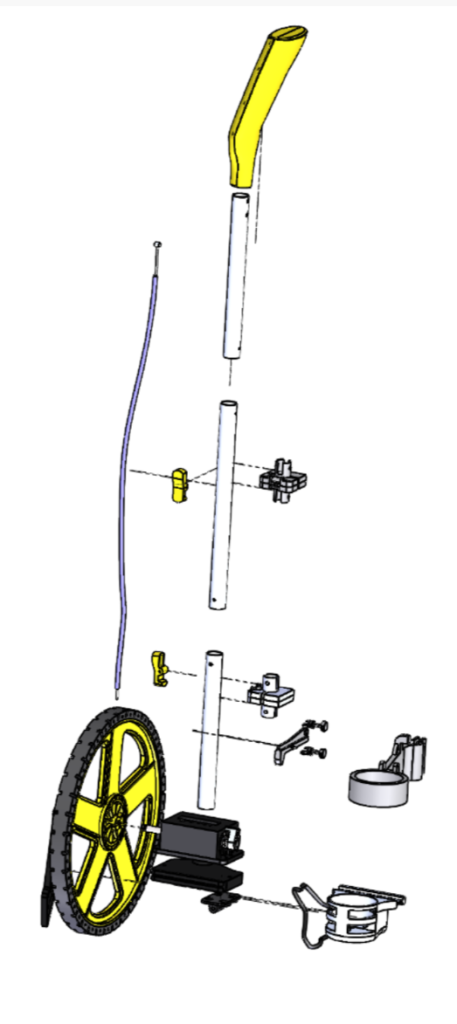

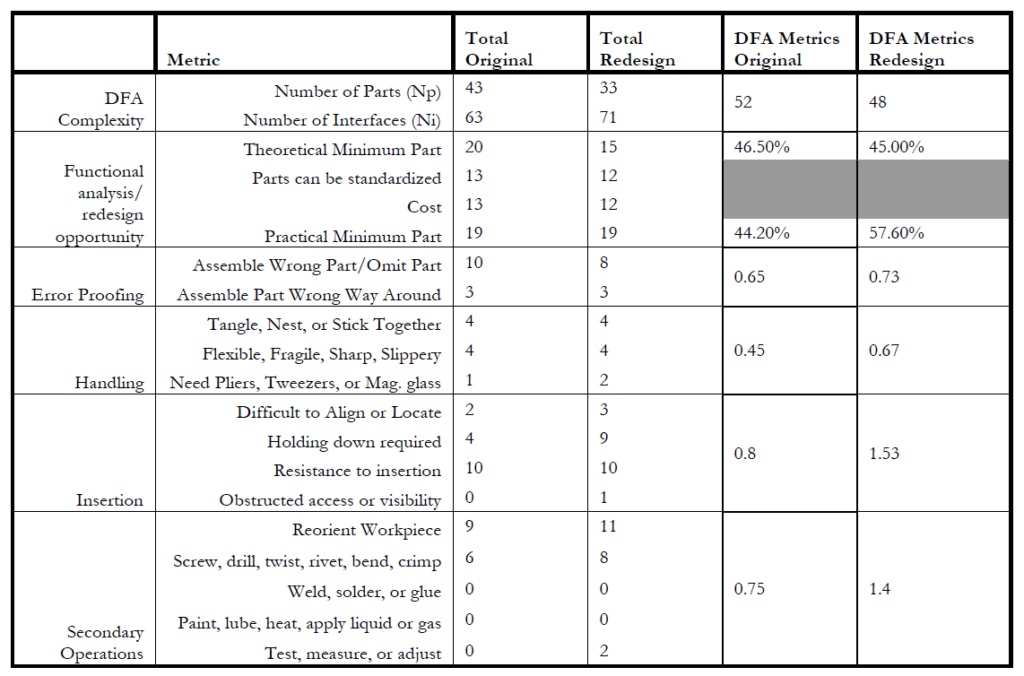

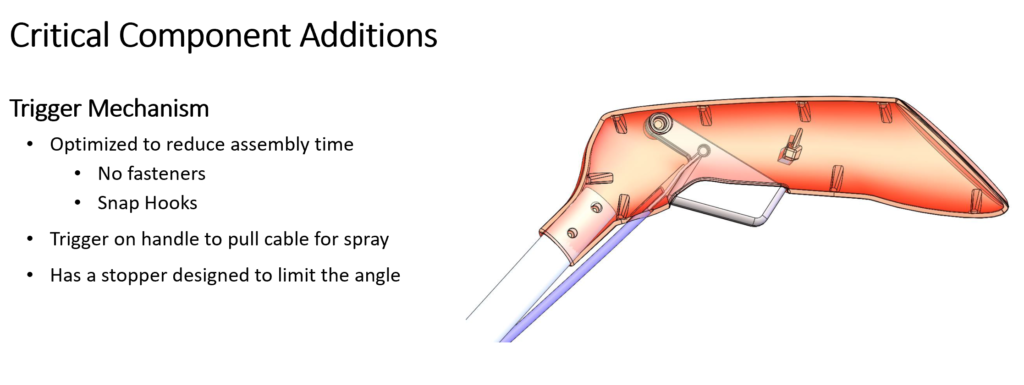

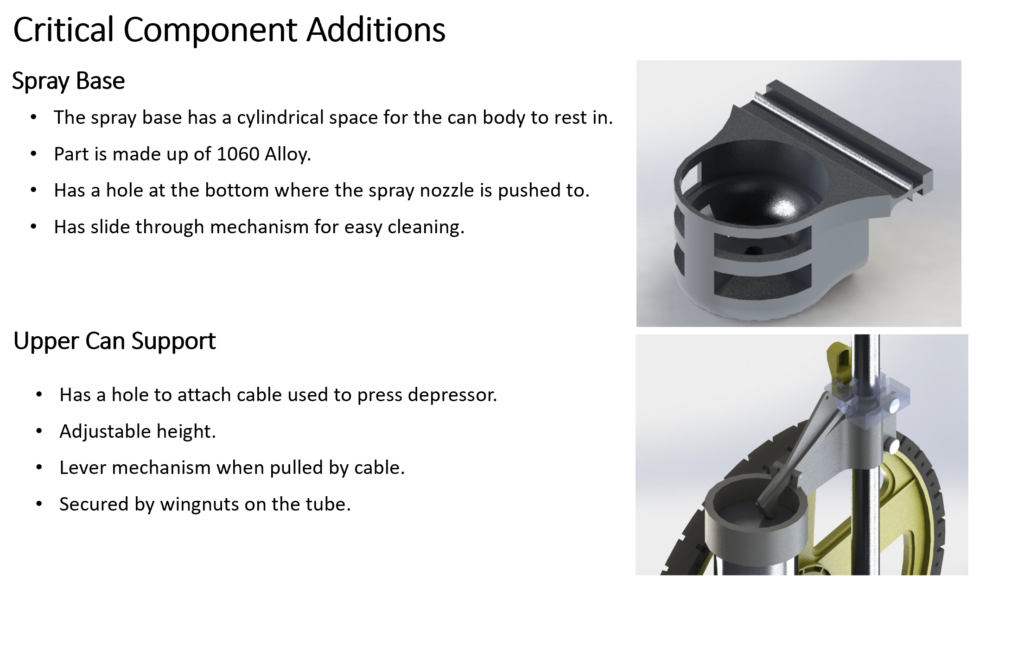

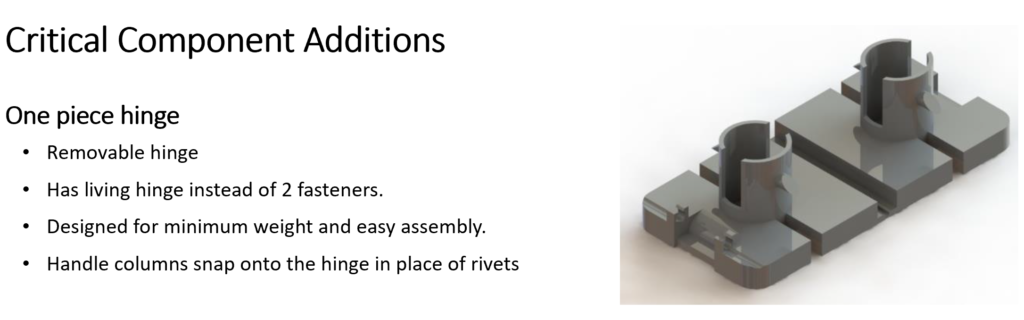

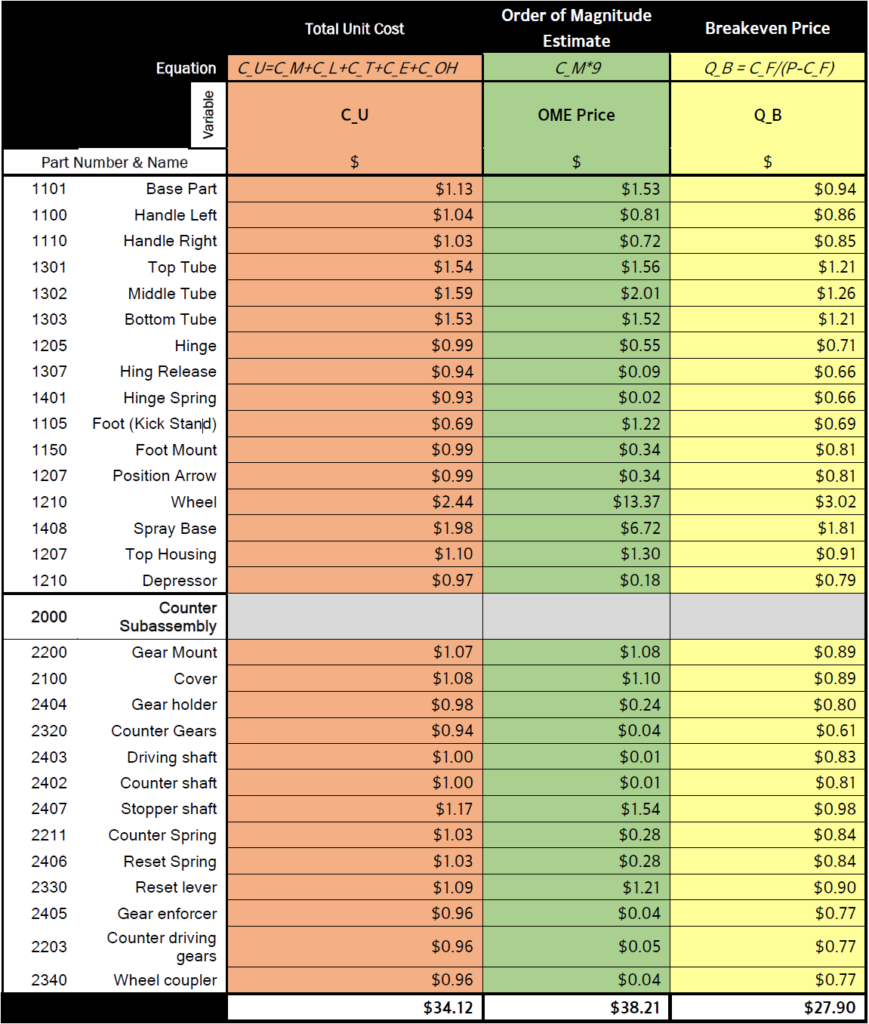

In this project, a common construction tool – the surveyor’s wheel, was reverse-engineered and redesigned without compromising performance, reliability, and aesthetics. Through the reverse engineering phase, work done made use of DFM, and DFA principles to analyze a consumer product in significant depth to identify areas of improvement and increase its functionality. The re-design of the product inculcated changes such as minute alteration of materials, the inclusion of a paint spraying wand (to allow for marking of the area measured), and DFA improvements (decrease of total part count). The new design allowed to reduce the cost of the product by 14%, and reduce the part count by 20 while improving its overall functionality.