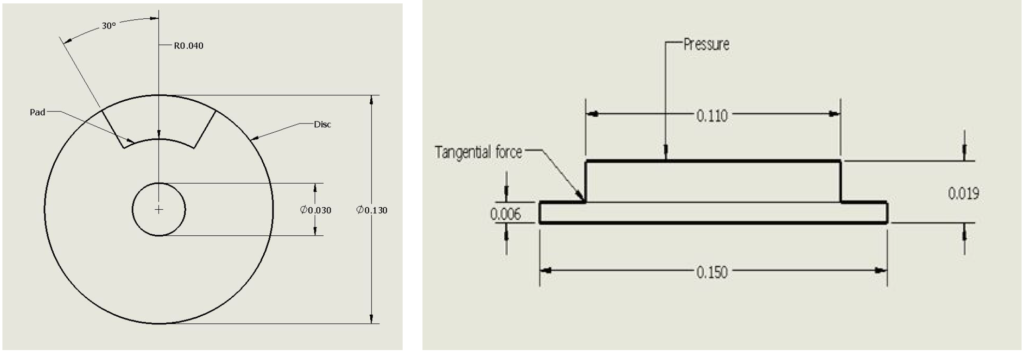

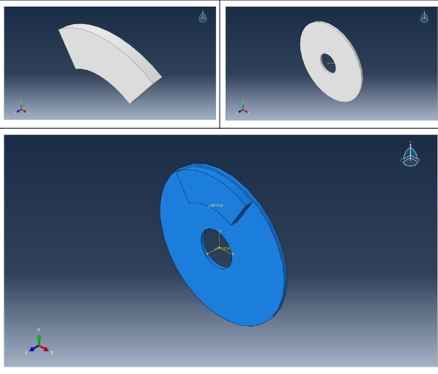

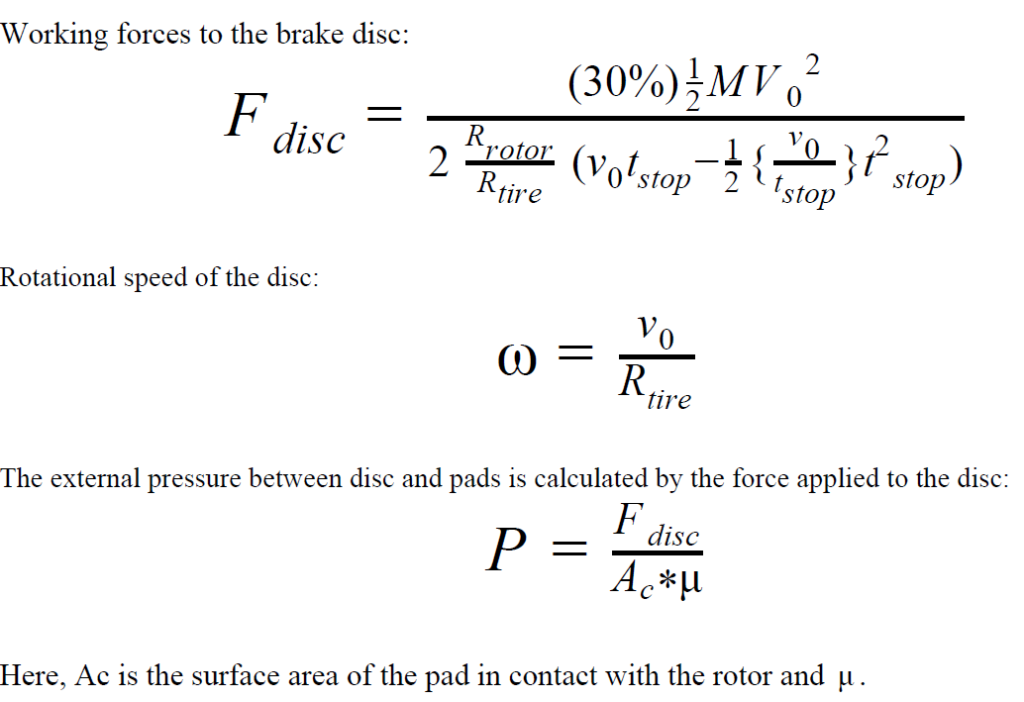

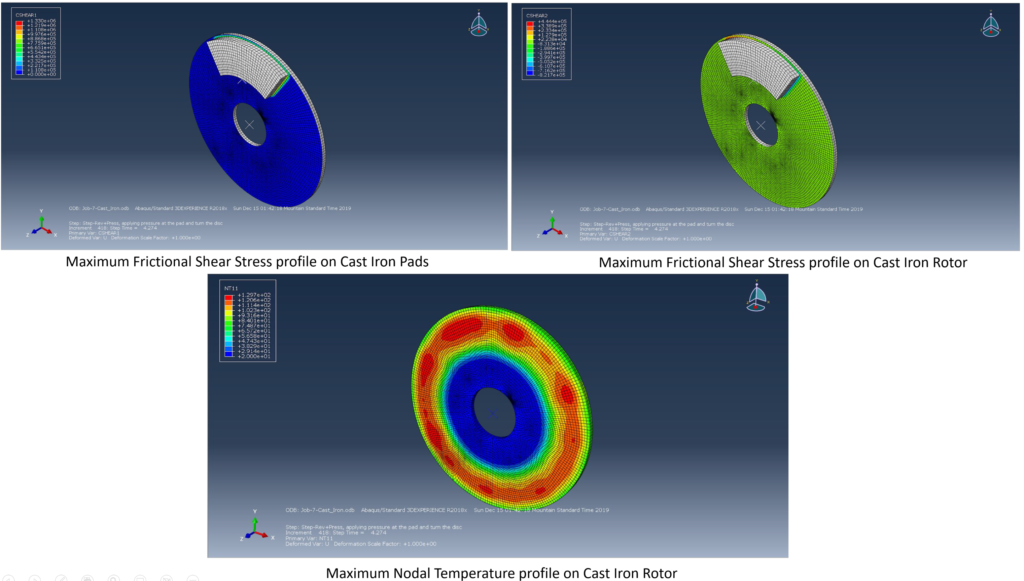

This study was performed as a part of coursework on Finite Element Analysis. The purpose of this project is to understand explicit modeling of temperature and stress build-up on the brake assembly during operation using ABAQUS CAE. A simplified model of the disc brake with brake pads and rotor with grey cast iron, carbon-carbon composite and stainless steel materials is considered for the thermomechanical evaluation. Working forces on the disc are applied in form of hydraulic pressure between the rotor and the brake pad.

For thermal verification, A 2D transient heat conduction on a cast-iron plate with dimensions similar to that of the 3D analysis was modeled and the results were found to be in satisfactory agreement.